Eureka! I finally found pictures of one of my guitars. I have a Steinberger GL2 that I acquired to restore in 1992. It took quite a lot of work to restore it, and it has since traveled around the world with me a couple of times. Let me tell you a story.

First, what makes it so unique? You're probably wondering. It wasn't the previous owner because there wasn't one. Yet, it wasn't exactly new. The guitar had been severely damaged and required a complete disassembly for cleaning and restoration.

So, how did it get in such a state? Well, let's start at the beginning. Until 1991, the one-piece Steinberger guitars, like my GL2, were made from carbon fiber in the Newburgh, NY factory. Although the guitars sounded great, the people at Steinberger still wanted to tweak the carbon fiber mix to get better resonance. One of the better sounding (to my ears) carbon fiber mixes includes Kevlar, which is the same stuff used in body armor. The one downside is that it is a challenging material to work with and was, at the time, almost unmachineable. So it will be difficult, once you have a carbon fiber/kevlar guitar shell, to drill holes for pots, jacks, and mill battery cavities. Today, the technology and manufacturing processes have advanced, and these could be 3D printed.

Steinberger tried, but my guitar is one they gave up on. It doesn't have a serial number, they broke the output jack hole, and the battery compartment was never fully routed. So it started life as a factory reject, committed to the scrap pile. To make matters more interesting, it was made sometime before Gibson bought Steinberger, closed the Newburgh factory, and moved everything to Nashville. For a few months, the entire world of Steinberger lived on some pallets in Gibson's Nashville warehouse. This was such a time.

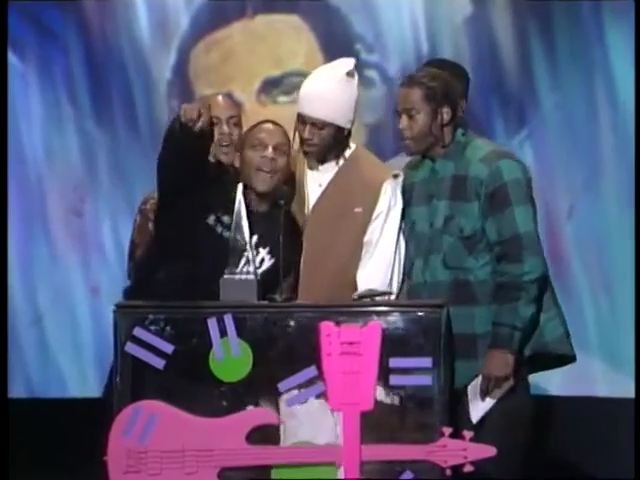

Then, on January 27, 1992, came the 19th Annual American Music Awards. The show's set designers decided to use various musical instruments as props and decorated several of the show's podiums with various Gibson family instruments. This is the bit I completely missed. I never saw the show when it aired, and I didn't record it, but fortunately I know what happened.

About a dozen factory-rejected instruments got the prop treatment. Gibson in Nashville had set up all the instruments to look like real working instruments and sent them in advance to the show. Dummy EMG pickups were installed in my GL2, but everything else was factory-correct. The show's prop department then got hold of the instruments and spray-painted them with 1/8" to 1/4" of fluorescent paint. I'm not kidding about that. Then the set decorators nailed or screwed the instruments to several podiums, which were then rolled out on stage for the presenters and winners to use.

At the time, I worked for Gibson in Artist Relations in Los Angeles, and my first sight of the prop guitars was when the crew returned them to the L.A. office after the show. I went through the entire pile (there were no cases) and figured there might be three guitars out of the whole lot that could be saved. And this was when I ran into Gibson's "kill all escapee guitars" policy. No matter how hard I tried, I couldn't get Gibson to sell me any of these prop guitars. They were all headed back to the bandsaw in the Nashville factory.

Then, I made my case for the Steinberger GL2. Fortunately for me, Steinberger was still under its own management despite being acquired by Gibson in 1987. My Artist Relations boss called the one person left in Steinberger management, and I asked what it would take for me to take it home. I then made the crazy lowball offer of $25.00 (which I figured would be countered) for an ugly pink, unplayable (at the time) prop GL2 guitar. The person on the other end of the phone said, "Well, we've already written off the guitar, so this is just found money, so yes." That was the quickest check I've ever written. I ensured I got a proper receipt so no one could later say I had stolen it from the pile.

When it returned from the show, the GL2 was in bad condition. All the notable damage from factory milling was on the rear at the output jack hole (ooops) and the partially finished battery cavity. At the factory, it had been set up with strings and even tuned before it was shipped out. It had dummy EMGs in it, so from the front, it looked brand new. It was also playable. It was set up to be a non-working display guitar.

However, the guitar now in my hands was different. Aside from the thick, bright pink paint job covering everything (even the strings), the crew had drilled a hole through the neck of the guitar between the second and third frets (where a dot inlay would traditionally be) and had screwed it into the green Chet Atkins solid body guitar below it (see top picture). For any other guitar, that would be right through the truss rod, but, being one-piece carbon fiber, this Steinberger didn't need neck reinforcement.

When I got it home, the worst-case scenario was that I'd use the big hole in the neck to hang it up on the wall, and it would be a nice piece of memorabilia. Over the next few days, I discreetly consulted a few people at Gibson. Roger Giffin ran Gibson's West Coast Custom Shop and was on the other side of the wall from my desk. He had designed the M Series guitar for Mike Rutherford of Genesis and had worked on Eddie Van Halen's 5150 guitar (a GL2T with the obligatory Van Halen paint job).

Roger assured me that the carbon fiber Steinbergers could take a severe beating and live through it, even with holes drilled in the neck. That gave me the confidence to attempt the restoration process, and I took the strings off and started scraping the fugly pink paint off the back of the guitar. The process was a labor of love, and the paint started to come off. I didn't use a paint stripper or chemicals because I didn't know how that would react with the existing finish.

The more paint that came off, the more I realized this would have to be a complete teardown. The neck and body had been relatively straightforward. I'd unscrewed the faceplate and removed the dummy EMG pick-ups and electronics, and the faceplate cleaned up nicely. Next, I took apart the S-Trem hardware. Oh my. Every nook and crevice had paint in it. I had to disassemble it and clean each piece individually. Screws, springs, saddles, you name it. The undercoat paint just wouldn't come off on a couple of pieces. So I gave up, and there's still paint on a couple of the knurled tuning knobs today, as well as some bright pink staring out from inside the unfinished battery cavity.

As I went to reassemble the GL2, I realized that my bargain price of $25 was about to be massively overshadowed just by replacing the dummy EMG pick-ups for working versions. Fortunately for me, I had some other options. I had a pair of Gibson 490R / 498T humbuckers lying around after I had replaced them with prototype '57 Classics in my Les Paul. I had never heard passive pick-ups in a Steinberger, and I was encouraged to find out what they would sound like. It turned out serendipitous because the guitar sounded great and immediately took off into that classic '80s rock sound with a chorus pedal.

I replaced the rest of the electronics in the GL2 with high-impedance pots (active EMG pick-ups use 25k low-impedance pots) and the exact same-value inductor that was used in the BB King Lucille guitar. I had previously tested several different capacitor values. I found it possible to squeeze out a tiny amount of gain from a passive circuit by judicious tone filtering. Depending on the pot setting, the capacitor/inductor/pot combination creates a very slight mid-range bump or the usual treble cut.

There were two more "repairs" to make the GL2 functional again. The first was finding a new home for the output jack. The original factory milling had applied too much force to compensate for the Kevlar composite mix. As a result, the larger drill bit for the output jack came all the way through, leaving no place for the output jack to anchor. I was never a fan of having the jack in the rear of the guitar because it would invariably catch on something. I put the output jack at the end of the lower bout, where one of the strap buttons had been. I made a hole for an enclosed barrel-type 1/4" output jack, which you typically find in an acoustic guitar. That took some doing, let me tell you.

The other "repair" was to the guitar strap buttons, as I had removed them. I made it a point to put the same locking strap system on all my guitars. I'd settled on the Jim Dunlop Straplok Dual Design Strap Retainers for my guitars. I could use any strap on any guitar. The only limitation would be whether I cared enough to match the strap Straplok colors with the Straplok buttons. Putting on new strap buttons was simple, and I'd made this conversion many times. Dunlop claimed they were good for 800 lbs. of pull, but in my experience, the pull force was only as good as the quality of the hole, the screw, and the wood. Now I was facing a carbon fiber guitar that was resisting all attempts to cut a new screw thread, as the new screws were slightly wider than the original factory screws and were stripping themselves. I also didn't want a stress fracture splitting the carbon fiber. So the next step is to enlarge the hole to accommodate the new screws. What I think I eventually did was enlarge the hole just big enough for the screws to grip and then pack the hole with toothpicks and wood glue. The theory is that the wood would crush first, saving the carbon fiber from splitting. Those strap screws have been holding firm for 32 years now.

Stop the presses! This guitar was just featured on an episode of Every Guitar Has A Story:

Copyright Disclaimer Under Section 107 of the Copyright Act 1976

Screen captures from the 1992 American Music Awards fall under "fair use" for purposes such as criticism, comment, news reporting, teaching, scholarship, and research. Fair use is a use permitted by copyright statute that might otherwise be infringing. Non-profit, educational or personal use tips the balance in favor of fair use.